When it comes to keeping industrial operations running smoothly in the UAE’s demanding climate, choosing the right shell industrial lubricants isn’t just a maintenance decision—it’s a business strategy. From high-temperature environments in Abu Dhabi to heavy-duty manufacturing in Dubai, the right lubricant can significantly impact equipment lifespan, energy efficiency, and overall productivity.

In this guide, we’ll break down how to select the best Shell lubricant for your specific application, what factors to consider in the UAE market, and how trusted suppliers like Apex Lube can help you make the right choice.

Why Choosing the Right Industrial Lubricant Matters

Industrial lubricants do much more than reduce friction. They:

- Minimize wear and tear

- Improve equipment efficiency

- Protect against corrosion

- Reduce downtime

- Extend machinery lifespan

According to industry studies, poor lubrication practices account for nearly 40% of mechanical failures in industrial settings. In a region like the UAE—where heat, dust, and heavy workloads are constant—selecting the correct lubricant becomes even more critical.

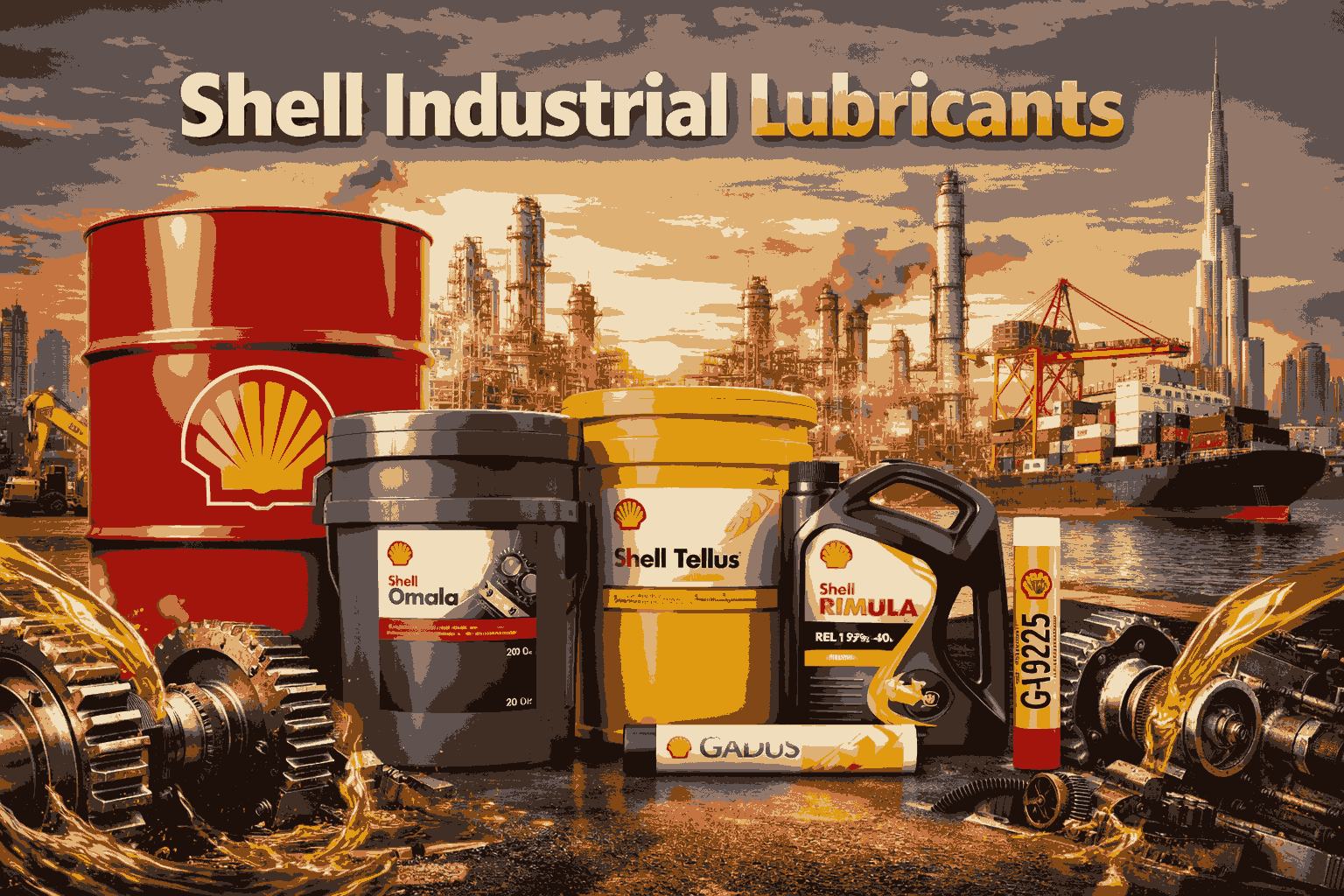

Understanding Shell Industrial Lubricants

Shell is one of the world’s leading energy and lubricant manufacturers, offering a wide range of solutions tailored to different industries. Their products are engineered with advanced additive technology designed to withstand extreme temperatures and harsh operating conditions.

Let’s explore the main categories and how to determine which one fits your needs.

1. Shell Tellus – For Hydraulic Systems

If your operation relies heavily on hydraulic machinery—such as construction equipment, manufacturing presses, or industrial lifts—Shell Tellus hydraulic oils are often the go-to solution.

Why It’s Ideal:

- Excellent wear protection

- Strong oxidation resistance

- Reliable performance under high pressure

In the UAE construction sector, where machinery runs long hours in hot conditions, Shell Tellus helps maintain viscosity stability and reduce system breakdowns.

2. Shell Omala – For Gear Systems

Heavy-duty gearboxes used in cement plants, steel factories, or marine operations require superior load-carrying capacity. Shell Omala gear oils are designed specifically for enclosed industrial gear systems.

Key Benefits:

- High load-carrying capability

- Extended oil life

- Protection against micro-pitting

Given the rapid growth of infrastructure projects in the UAE, gear reliability is essential. A quality gear oil can reduce maintenance intervals and lower operational costs over time.

3. Shell Rimula – For Diesel Engines

For fleet operators and industrial transport systems, engine performance is everything. Shell Rimula is formulated to protect diesel engines from soot, acid buildup, and wear.

Best For:

- Heavy trucks

- Construction vehicles

- Industrial generators

With fuel efficiency being a major concern in logistics and transport sectors, selecting the right engine oil directly impacts fuel consumption and engine longevity.

4. Shell Gadus – For Bearings and Grease Applications

Bearings operating under high loads and temperatures need specialized grease solutions. Shell Gadus greases are engineered for extreme pressure and durability.

Applications Include:

- Manufacturing plants

- Mining equipment

- Steel processing facilities

In environments where dust and contamination are common, high-quality grease ensures consistent protection and prevents costly shutdowns.

Factors to Consider When Choosing Shell Industrial Lubricants in the UAE

Before selecting a product, consider the following:

1. Operating Temperature

The UAE’s summer temperatures often exceed 45°C. Ensure the lubricant has high thermal stability.

2. Load Conditions

Heavy machinery requires lubricants with strong load-carrying properties.

3. Industry Requirements

Marine, construction, manufacturing, and oil & gas sectors each have unique lubrication demands.

4. OEM Recommendations

Always follow the original equipment manufacturer’s guidelines for optimal performance.

5. Environmental Conditions

Dust and sand exposure can accelerate wear. Choose lubricants with strong contamination resistance.

Why Work with Apex Lube?

Choosing the right lubricant is only half the equation—working with a knowledgeable supplier makes all the difference.

Apex Lube provides:

- Expert product recommendations

- Reliable stock availability across the UAE

- Technical support for industrial applications

- Competitive pricing

By partnering with an experienced distributor, businesses can ensure they’re not only purchasing the correct product but also optimizing long-term maintenance strategies.

The Cost of Choosing the Wrong Lubricant

Cutting corners on lubrication can be expensive. Equipment downtime in industrial sectors can cost thousands of dirhams per hour. Poor-quality or incorrect lubricants may result in:

- Premature component failure

- Increased energy consumption

- Higher maintenance costs

- Production delays

Investing in the right shell industrial lubricants today prevents costly repairs tomorrow.

Final Thoughts: Making the Right Choice

Selecting the right shell industrial lubricants depends on your machinery type, working environment, and operational demands. Whether you need hydraulic oil, gear oil, engine oil, or grease, understanding your specific requirements ensures maximum equipment performance and durability.

In the UAE’s fast-paced industrial landscape, smart lubrication choices are a competitive advantage.